Have you ever wondered where exactly in your supply chain is the most potential for cost savings, better sustainability performance and safer products?

Many businesses know that there are some negative influences in their supply chain, but many of these businesses do not know how to address them. This is where supply chain mapping helps you regain control over your business and understand what is going on at every step in your supply chain. You will only have to draw the right conclusions in order to deal with what you find out.

Some time ago, when we were auditing a vertically integrated supplier, with both garment and fabric manufacturing, we had a look at the materials going in and the products coming out. We also had a look at the energy and water consumption in the production process. We made a rough calculation of the water and energy consumption per product group, and the results were really promising! However, in the factory we had seen some practices that were far from world class standard, so the KPIs we calculated did not in fact match what we actually saw.

Therefore, we engaged with the supplier in order to understand more about their business set-up, and we found out that they were using subcontractors for some of their work. That was quite a surprise, but once we knew about their real business set-up, we were able to address the processes that were causing complications, and that were inefficient and big cost drivers.

This article will help you understand what supply chain mapping is, and what first steps you should take to implement it with the aim of avoiding similar surprises.

What is supply chain mapping?

Supply chain mapping means following your products and materials through the supply chain. Therefore, you need to establish a documentation structure of all the materials, processes and shipments that are involved in bringing your goods to market.

You do this in order to understand where your products are being produced and where the materials for your products come from.

Most of the time you will need to go further back in the supply chain, via your first tier of suppliers, for example, the garment or footwear manufacturers, then even further back to the dye-houses and fabric manufacturers.

Have a look at the following flowchart. It shows a typical supply chain in the textile sector. But most other sectors have a similar structural set-up in their supply chains. When you are mapping all the players in your supply chain, you can imagine how complex this picture can get. But it becomes even more complex if you source via agents, because then the agents come between your company and the suppliers. This results in an unclear and confusing structure with a lot of dead ends. You may not have an overall view of the actual manufacturing entities at all. So you will not even be seeing the tip of the iceberg!

Therefore, the best starting point is when your sourcing department has direct contracts with the manufacturers in the first tier. Then these manufacturers can help you with the next step, to reach their suppliers and so on. In this way you will be able to understand what is going on in your supply chain.

What are the reasons for mapping your supply chain?

There are many different reasons for mapping your supply chain. For example, you may have had a chemical compliance failure in one of your leather products and you need to find the root cause. If you know your supply chain’s structure it will save you a lot of time and money.

So, knowing your supply chain is essential for managing your compliance risk. It is also beneficial for focusing on your sustainability programs. When you think about your main risks you will quite often find them further upstream in your supply chain.

If you wish to ensure that your programs are well implemented, supply chain mapping is also helpful to see if your efforts are bearing fruit.

As we learned from our previous article entitled the Sustainability Vision for the Textile and Fashion Sector, consumers are becoming increasingly interested in where their products come from, and they are not afraid of sharing their findings on social media. So, you may have consumers asking you where your products are produced, and they would expect you to respond by being transparent about your supply chain. You may remember that just a few years ago there was an outcry from a lot of brands when the possibility of publicizing their first-tier suppliers was mentioned. Now we are actually seeing the first players making public their second-tier and subcontractor suppliers. Therefore, knowing your supply chain will eliminate any fear of reputation-damaging disclosures.

Furthermore, you could expose your more sustainable products and materials, and communicate them to your customers. Perhaps you are already thinking beyond the first steps and wish to trace and certify more sustainable materials. This might also enable you to address a new target group.

Another reason might be that you intend to improve your relations with your suppliers, and ensure fair and stable conditions in the supply chain. This will not only help you improve your reputation with your customers and suppliers, but it will strengthen the core of your business and increase your profits.

The Business Case for Supply Chain Mapping

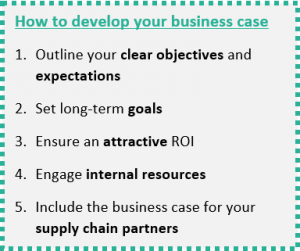

But beyond those reasons, do you know if there is a business case for you to actively map your supply chain?

Let’s take a closer look at the above picture. The arrangement you see is one common structure to use for your business case and all your sustainability reports.

- Do you wonder where in your supply chain you can avoid costs?

Have a look at the Compliance & Risk Minimization sections.

Have a look at the Compliance & Risk Minimization sections. - Are there any possibilities to save costs? Well, you will find them by examining cost savings and integrated operations.

- Avoiding and saving costs are a good start, but you also need to develop your business and generate additional value. That is what you will do by means of Innovation & Market development as well as Brand & Reputation enhancement.

A clearly defined business case is essential for your mapping project and when you develop it; be clear about your goals and include your supply chain partners in your considerations. What is their business case? They may wish to be known by you, to have more stable relationships and to work with you to find joint solutions. So remember: teamwork is your recipe for success!

First implementation steps to focus on

*You can gather information via, for example, a questionnaire you send out to your suppliers, agents and/or vendors. You may use an Excel spreadsheet, call them or visit them. However, there are also software tools available, where you can invite your suppliers to join, share their information, and then connect to their own suppliers, inviting them to join the platform and share their information, in a cascading process.

Success Factors

When driving your supply chain mapping project collaboration is the key to success. Therefore, you need to engage with your suppliers. It is extremely important to realize strong supplier communication, where you communicate clear objectives, ensure a fair and regular supplier engagement, and track the overall process. Make sure that you still check and verify the information you collect. Check that, for example, the supplier address you have been given actually has a factory on-site and is not just a billing address.

Do not shy away from devoting your time, effort and resources for collaboration, and start developing your own capabilities now! In order to make your supply chain mapping successful, you need to understand that you can only accomplish this together with your partners.

Industry best practice examples

In conclusion, we will have a look at two good examples of how to visualize your supply chain. Please follow the links to get a better impression.

By publishing the supplier’s network under the name “the footprint chronicles” Patagonia set an example a few years ago, of how a transparent supply chain can improve your reputation, and show social and environmental responsibility. They also demonstrate how to make it visually attractive, and include their 2nd tier suppliers on the map.

Furthermore, Patagonia publishes information about specific projects conducted by suppliers, such as, for example, water-saving projects and what the actual results are.

Marks & Spencer’s interactive supplier map shows the number of suppliers per location as well as the types of products produced. You can dig down into the supply chain, selecting either clothing or food, then dig down into the countries, followed by the actual manufacturer, getting the basic information about the manufacturer.

Once you have done your mapping you can move on to the traceability of your materials and products. You may now wish to move onto this step, and trace and measure more complex issues in the supply chain.

If you need help mapping your Supply Chain or with the measurements, please contact us for a customized offer.

Meet our team.

Read more about the Business Case.

Read more about The Sustainability Vision in the Textile and Fashion Sector.

Read more about Software Solutions.

If you wish to receive regular news updates from us, please subscribe to our Newsletter.

- United Nations Global Compact (UNGC), Business for Social Responsibility (BSR) (2014). A Guideline to traceability. A practical approach to advance sustainability in global supply chain. Homepage: https://www.unglobalcompact.org/library/791

Leave a Comment