Once you are done with mapping your supply chain, you will have the possibility to trace your products and materials in detail.

The traceability of products and materials is becoming increasingly important across multiple industries. As food safety issues kept the food industry on its toes in the past, regulations such as the EU General Food Law made the industry trace its products and implement special traceability systems that allowed it to identify where its products had come from, where they were going, and also to provide this information to the relevant authorities. This is necessary to ensure consumer health and safety and the food industry shows that traceability is possible. Therefore, industries such as apparel, information and communications technology, automobile and jewelry, have started tracing their products in various ways and pursuing a range of varying goals.

This article shows why traceability is so important in all industries, what different methods there are to trace products, and how your company can develop and implement a traceability scheme.

If you don’t have the time, resources or knowledge to develop and implement your own traceability scheme, Leadership & Sustainability is happy to offer its expertise. We invite you to book an appointment via our online booking tool or you can leave your contact details here.

What is traceability?

ISO defines traceability as follows: “Traceability is the ability to identify and trace the history, distribution, location and application of products, parts and materials.”

Depending on the context, several modifications to that definition exist. Traceability is often linked to sustainability, where it is used as a tool to assure and verify sustainability claims associated with commodities and products, thus ensuring good practice and respect for people and the environment along the supply chain.

To assure traceability along the supply chain, it is necessary to develop systems that record and follow the trail of products in order to provide information about the components of products and materials as well as information about transformations throughout the value chain. The success of your tracking efforts can be reflected in increases in product quality and safety, as well as in labels that link back to a proven or certified traceability scheme.

There are already schemes that, for example, ensure that minerals are not sourced from armed conflict zones (“conflict minerals”), or programmes that certify the use of products that are grown in sustainable cultivations whether they are related to food (e.g., coffee or cocoa) or other commodities (e.g., wood or cotton). These schemes prevent consumers from unknowingly financing conflicts, and also have a huge impact on the reduction of carbon emissions and on fighting deforestation. While some schemes cover a wide range of products such as the Rainforest Alliance or Fair Trade, most traceability schemes are designed to trace one specific commodity only, for example, the Kimberly Process for diamonds or the Marine Stewardship Council for fish.

Why does traceability matter?

As mentioned above, traceability schemes have become an important part of the sustainability landscape, and can ease social and environmental conflicts. They also have the potential to increase the value of your business.

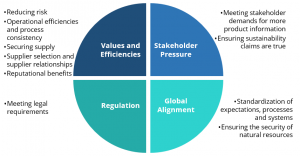

As can be seen from the figure below, tracking your products supports your business to have a better performance by lowering your costs, reducing the lead time and enabling greater efficiency. It also allows you to gain back control, hence securing your supply and improving the quality of your products. In terms of risk and reputation management, traceability gives you a greater capacity to manage risks and the opportunity to verify your sustainability claims. Moreover, it is the key to better compliance with existing regulations and prepares you for future regulations.

To find out more about the benefits of traceability, please read our article:

Implementing Supply Chain Mapping into your Business – here is why and how you should do it!

How does traceability work across the supply chain?

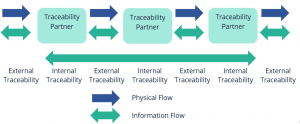

As can be seen from the figure below, traceability management across the supply chain involves a combination of a flow of information with the physical flow of traceable items.

Each traceability partner must perform different roles within the supply chain, but all the players must follow the basic agreed-upon steps of the traceability process. These partners can be, for example: authorities, processors, manufacturers, primary producers, carriers, third-party logistics providers, retailers, point of sale or service operators, warehouses and distribution centers. In order to achieve traceability and transparency across the supply chain, all traceability partners must achieve internal and external traceability, and work together as a team. The traceability data that are exchanged across the supply chain must include the following information:

- Who? Party [Identification + data elements]

- Where? Location [Identification + data elements]

- When? Date / Time

- What? Traceable item [Identification + data elements]

- What happened? Process or event [Identification + data elements]

Internal traceability

Internal traceability means that one partner receives one or several instances of traceable items as forms of input that go through internal processes in order to create one or several instances of traceable output. Therefore, every traceability partner has to maintain the agreed-upon data linking the input into a transformation process with the output, and linking the original and final location after this movement.

External traceability

External traceability is characterized by a traceable item that is physically handed over from one traceability partner to another. Each partner should be able to trace an item back to the direct source and to identify the direct recipient of that traceable item. This is called the “one step up, one step down” principle.

Depending on the purpose of the scheme, there may be different needs with regard to holding and publishing traceability information: However, the traceable item’s source and recipient must communicate and record the identification of at least one common level of traceable item within their respective systems. This ensures an efficient information flow of data when tracing back or tracking forward.

Which models can be used for your Supply Chain Traceability?

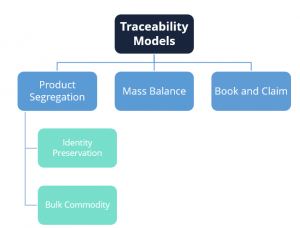

In their “Guide to Traceability,” the UN Global Compact defined three main models in terms of how traceability schemes trace sustainability claims. These models suggest different approaches to tracking a claim and assuring it at each point in the supply chain.

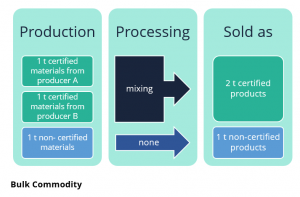

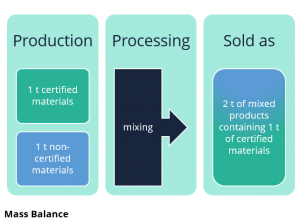

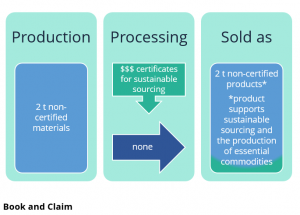

The proposed models are differentiated by the extent to which certified and non-certified materials are permitted to mix, as well as by claims that can be attached to the final product. Models with less stringent controls around the handling of certified and non-certified materials are less complex and thus less expensive. However, wherever possible, the type of certification and model of traceability used should depend on the sustainability claims and the materials being traced rather than the cost of implementing the model.

Product Segregation

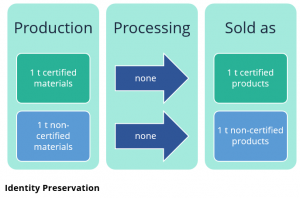

Product Segregation means that certified (e.g., organic) materials and products are physically separated from non-certified materials and products. This separation has to be adhered to at every stage along the value chain to ensure that the certified and non-certified products are not mixed. As a result, the consumers receive products that can be fully traced back to a certified source and are 100 % certified materials.

There are two different types of product segregation: Bulk commodity and identity preservation. While both models separate certified from non-certified materials, the bulk commodity model allows the mixing of certified materials from different producers who all have to comply with the certification standards. The identity preservation model does not allow any mixing throughout the value chain to provide traceability from a specific plantation or primary processor for the final users.

Mass balance

The use of the mass balance model is common for products and commodities where segregation is too expensive or not achievable for other reasons, for example, for physically identical products such as cocoa, cotton or tea. Other than with product segregation, certified and non-certified materials can be mixed with the mass balance model. However, there is one requirement for this: The exact volume of the certified materials entering the value chain must be controlled and an equivalent volume of the certified products can be sold as being certified. As a result, customers may not know whether their specific share of the product contains certified or non-certified materials, or a mixture of both. UTZ Certified, for example, offers the mass balance system in order to boost sustainable production. This way, more farmers are able to benefit from the advantages of sustainable farming, which might support them in increasing the supply of certified products.

Book and Claim

Another approach is the Book and Claim model. This model differs a lot from the other two, as it does not seek to have traceability at every stage in the supply chain. This model is used when the traceability of certified products is – for whatever reason – not fully possible within the supply chain. Book and Claim relies on the link between the volumes of certified materials produced and the number of certified products purchased at the end of the value chain. Certified and non- certified materials flow freely throughout the supply chain. When these mixed materials are traded as being non-certified, the company can obtain sustainability certificates for the volume of certified materials it is putting into the supply chain, and this right to claim a certified source is then traded via a trading platform. The certificates are purchased from companies that want to make sustainability claims without having sustainably sourced products. They support sustainable production through buying certificates.

How to develop a traceability scheme for your company

The UNGC Guideline to traceability recommends seven steps to implement traceability in practice. A simplification of this complex process is shown in the graphic below and gives you an idea of what is important to consider. For further information on the implementation steps, please contact us and read the UNGC ‘A Guideline to traceability’ and the Global Traceability Standard GS1.

Firstly you define your purpose and scope. Therefore, you map your material supply chain inputs, looking at all the procurement categories and tracing products back to their raw materials. This will help to identify which raw materials or commodities carry the greatest risks of being involved with adverse effects and make the greatest possible improvements.

After that you need to gain a full understanding of all the relevant sustainability issues regarding these commodities and find out whether tracking your products is the best way to mitigate the risks. In order to consider the sustainability issues holistically, it is recommended you take a lifecycle approach.

Once you know your sustainability risks, it is time to develop your business case for traceability and to take action. If there is an existing traceability scheme, get involved in the most appropriate way. The schemes serve as a resource for businesses pursuing traceability and a forum for exchanging best practices. If there is no existing scheme for that commodity, reach out to your peers and stakeholders to encourage them to start one.

The next step is to engage internally with the key staff, and to develop solid internal practices and processes. Make sure that your internal policy is reflected in all the relevant procurement processes, and that your commitment to traceability is supported by senior management.

As soon as traceability is understood internally, it is time to engage with your suppliers and make sure they understand the benefits they will gain from it. You also need to know if they can meet the requirements, as well as to educate them about the traceability scheme and their responsibilities.

The final step of successfully implementing traceability into your company’s business is: Carry on! It might be difficult from time to time and it can be frustrating when initially it seems that you will not be able to achieve your objectives. However, those who have been doing it the longest see some pay off after at least a few years of engagement. At the same time, evaluate over time whether the traceability scheme is successful in mitigating the relevant risks and achieving your sustainability objectives.

If you need any assistance with developing and implementing your traceability scheme, please book a free 30-minute appointment and let us support you in fulfilling your goals.

Leave a Comment